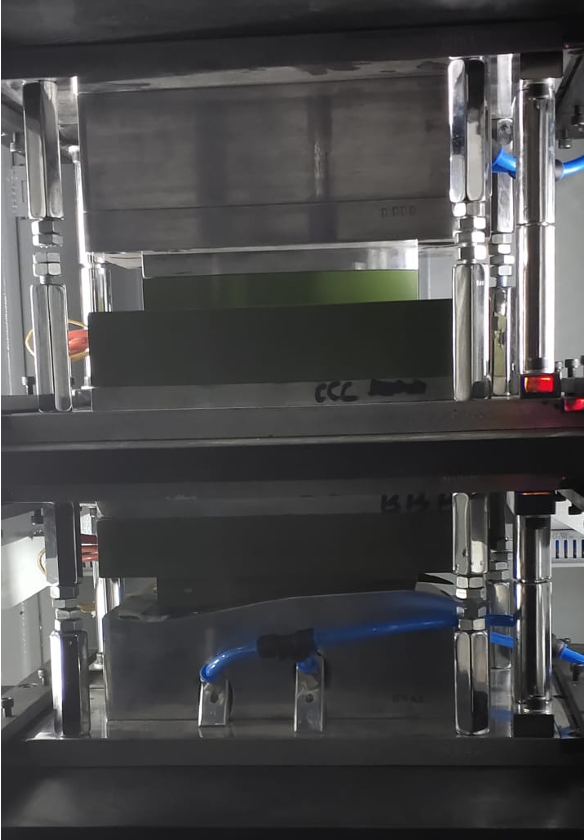

PP Corrugated box Ultrasonic Welding Machine

The PP corrugated box ultrasonic welding machine is engineered to join polypropylene corrugated materials using high-frequency ultrasonic vibrations. This technology creates strong, precise welds without adhesives, ensuring lightweight and durable packaging. Ideal for fast production cycles, it minimizes thermal distortion and enhances efficiency. Commonly utilized in the packaging industry, it guarantees high-quality seams for reliable corrugated box

Specifiaction

| product model | Prime 2020 |

| working Frequency | 20KHZ |

| power | 2000 watt |

| Working Air Pressure | 2~4 bar |

| input Voltage | 220v |

| Weight | 85~90 kg |

| Size | l 900*900*2300mm |

| welding head Trip | 75mm |

Ultrasonic plastic welding machine with Rotary Table

This machine can manually place the material, automatically ultrasonic weld, and then be equipped with a pneumatic actuator to grab the product. It can also be designed to manually place the material, automatically weld and then manually pick up the product at the end, or a higher-end full automatic production

Advantages

By choosing the ultrasonic rotary welding machine with actuator

- you can batch weld work,

- increase efficiency, and output,

- Save labour.

- The production process is diversified, you can choose the ultrasonic welding machine per your different needs and conditions.

Hot Plate Welding Machine

A hot plate welding machine is a specialized device used to join thermoplastic materials by heating two surfaces with a heated plate. The process involves melting the surfacesand applying pressure to create a strong, durable bond once cooled. This technique is widely used in industries such as automotive, medical, and consumer goods for producing high-quality, reliable components. Its versatility makes it suitable for various shapes and sizes of parts, ensuring efficient and effective manufacturing processes.

Feature-

- 1.pneumatically operated hot plate welding machine.

- 2.The three-axis is driven by cylinder, and the hot plate is driven by the back rail arm.

- 3. PLC, man-machine interface (7 inches) using Delta brand.

- 4. Heating temperature PID control in accuracy and stability

- 5. Programmable pneumatic clamp, ejector and vacuum function for welding tooling action

- 6.Alarm display show machine error to guide machine problem shooting, alarm history for further checking;

- 7.Operator authorization management with password

- 8.Optical fence and safety sensor applied for human safety protection

- 9.Machine set back to home-position by one touch operation

Benefit:

- Long machine duration in stability and mechanical precision;

- High welding ability in good jointing result

- Economical equipment cost;

- Easy operation and convenient management

Prodcut Range

Hot plate tool

Hot plate Machine Control Panel

Heater & Sensors

Heat Staking Machine

Heatstaking machines are beneficial when joining two parts that consist of different material which cannot normally be ultrasonically welded.

Features

- Although each machine is custom built for its specific application, the following information details typical machine features.

- Rugged, tubular steel frame construction using the highest quality components

- Safety guarding

- HMI /MMI process controls provide easy set up and repeatability of control.

- Quick disconnect heater elements

- Palm buttons and emergency stop

- Controlled air flow

- Heater Burnout Alarms (optional)

- Closed loop systems for process monitoring (optional)

- Light Screens for protection (optional)

- Touch Screens (optional)

- Digital timer for weld time and post-cool

- Auto & Manual Setup mode head down for probe alignment with component

- Prewired and preprogrammed for optional slide kits, post cool, and fixture clamping.

- LVDT for slide conformation (optional)

Benefits

- Cost effective

- Short Cycle Times

- Tight Assemblies

- Excellent repeatability and process control

- Elimination of mechanical fasteners and adhesives

Applications

- Thermal press applications include heat staking, inserting, embossing, date coding and degating.

- Automotive industry for door panels, map pockets, light-pipe staking, consoles, arm rests and switch clusters.

- Medical applications include blood-processing equipment, chemical pumps, fittings, flow meters, IV drug delivery and surgical instruments.

- Consumer Product applications include personal computers, portable telephones, laser printers, copy machines, video games, speakers and appliance components.

- Industrial applications include conveyor systems, gears, pulleys, couplings, and motor housings. Thermal presses are also used in Toy Manufacturing and the Sporting Goods industry

Spin Welding machine

These machines are ideal for assembling automotive and motorcycle filters, reverse osmosis (RO) water purifier filters, water pitchers, and cylindrical workpieces.

Spin welding is a technique used to bond circular thermoplastic components by pressing them together while one part rotates against the other. One component remains fixed within a fixture, while the other spins under pressure. The heat generated through friction melts the interface, allowing the materials to fuse and form a durable, airtight seal.

Compatible Materials: HDPE, PP, PE, PVC, ABS, PET, nylon, and more.

Application Range: Extensively utilized in the electronics industry.